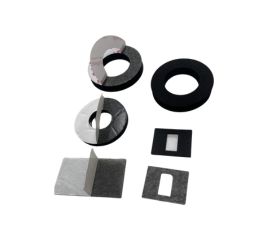

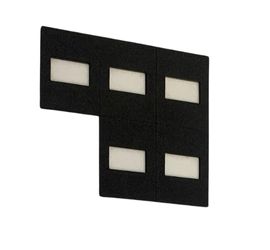

Our custom-made foam die cuts are designed with precision to meet diverse application needs. Available in various shapes and sizes, these foams feature an adhesive layer for seamless functionality. For added convenience, multiple foam and adhesive layers can be laminated, providing ease of application and tailored solutions for specialized requirements. This versatility makes our die-cut foams an optimal choice for high-performance and user-friendly applications.

Our laminated foam solutions cater to dynamic product requirements by integrating a diverse range of materials with precision. We expertly laminate foams, woven and non-woven materials, paper, films, and tapes, offering a wide variety of thicknesses and surface finishes. This versatile approach enables us to create tailored solutions that meet complex and evolving industry needs, ensuring functionality and adaptability across multiple applications

Our self-adhesive foam solutions are designed to simplify product usage and application by layering a variety of foams with adhesive tapes or coatings. With options spanning various foam densities and adhesive types, we ensure compatibility with diverse surface applications and adaptability to different work environments. This versatility makes our self-adhesive foams an ideal choice for efficient and reliable solutions across a wide range of industries.

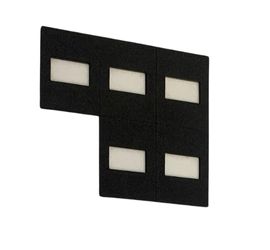

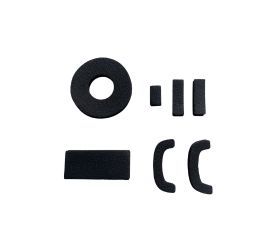

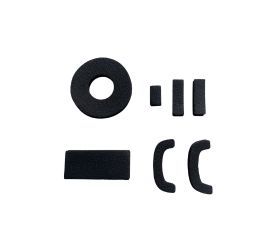

Our NBR nitrile foams are crafted as closed-cell solutions, offering exceptional performance and versatility. Available with or without adhesive layers, these foams can be precision-punched or die-cut to meet specific dimensional requirements. Thanks to their closed-cell structure, they provide excellent water repellence, thermal insulation, and an optional fire-retardant feature for enhanced safety.

NBR foams are also highly resistant to oil and grease, making them a reliable choice for demanding applications across various industries. Their durability and functional properties ensure consistent performance in even the toughest environments.

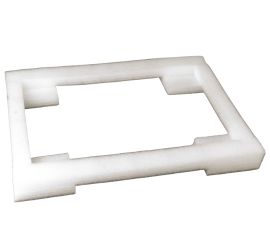

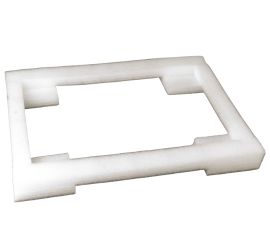

EPE (Extended Polyethylene) foams are lightweight, durable, and versatile materials, making them an ideal choice for protective packaging solutions. Renowned for their excellent cushioning properties, these foams safeguard valuable equipment and products during transportation and storage. Their flexibility and shock absorption capabilities ensure the integrity of items, even under demanding conditions.

We specialize in slitting and cutting EPE foams to desired dimensions and performing thermal bonding for multiple layers and geometries. Our advanced setup includes single-station manual thermal bonding as well as two-station automated bonding machinery, ensuring precision and efficiency.

EPE is 100% reprocessable and recyclable, making it a sustainable packaging solution that effectively replaces Styrofoam. Its protective characteristics and robust performance make it a forward-thinking choice for modern packaging needs.

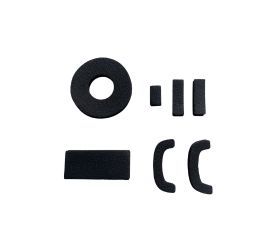

EPDM (Ethylene Propylene Diene Monomer) foams are highly resilient and versatile, making them an ideal choice for applications requiring durability and precision. They offer excellent thermal insulation, water resistance, and weatherproofing capabilities, ensuring reliability in challenging environments. With chemical stability that resists UV radiation, oxidation, and a wide range of temperatures, EPDM foams deliver consistent performance for demanding industries.

Designed for adaptability, EPDM foams are utilized across various functional applications. Through custom die-cutting and punching to precise specifications, they meet unique requirements effortlessly. Additionally, multiple layers can be bonded to create complex geometries and enhanced functionality, providing tailored solutions for modern engineering challenges.

Felt tapes offer versatile solutions for a range of applications, combining functionality with ease of use. These tapes are crafted from durable felt material and are designed to provide cushioning, noise dampening, and protective insulation. Their adhesive backing ensures effortless application on various surfaces, making them a reliable choice for industries requiring precision and efficiency.

With flexibility to adapt to different environments and requirements, felt tapes are commonly used in automotive, electronics, and general manufacturing industries for sealing, vibration damping, and abrasion protection. Their ability to deliver consistent performance highlights their value in both practical and specialized applications.